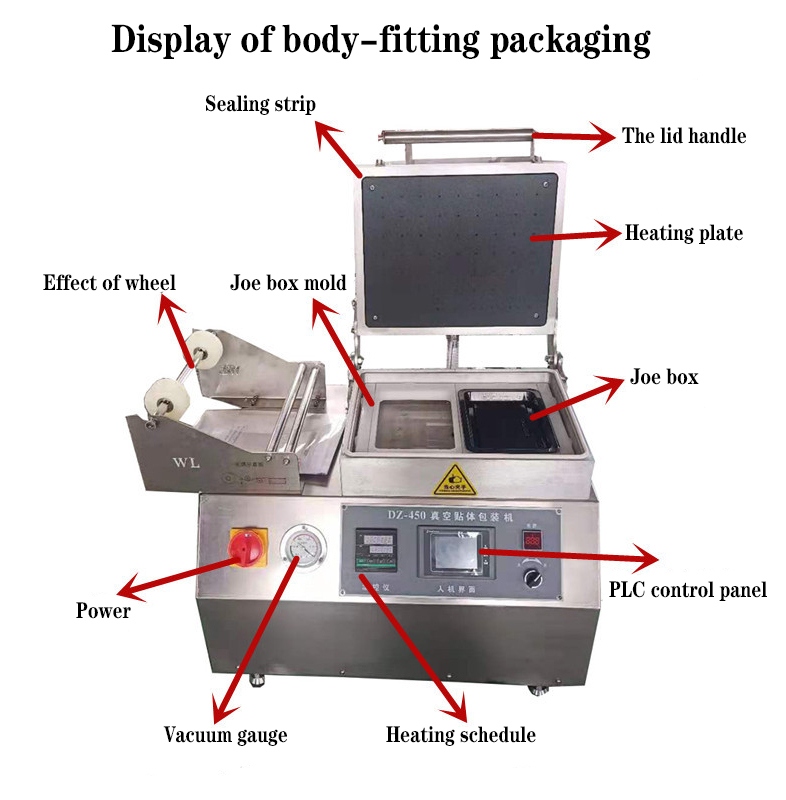

Commercial Skin Vacuum Packaging Cold Meat Food Vacuum Packaging Machine

.jpeg)

| Name | Data Parameter |

| Name | Vacuum fitting packaging machine |

| Equipment dimensions | 820*600*530mm |

| Total power | 2.5KW /h |

| Actual working size of studio | 310*390*55mm |

| Machine material | Aluminum alloy, 304 stainless steel |

| Film width | 360 mm |

| Vacuum pump efficiency | 20m³/hour |

Commercial Skin Vacuum Packaging Cold Meat Food Vacuum Packaging Machine

.jpeg)

.jpeg)

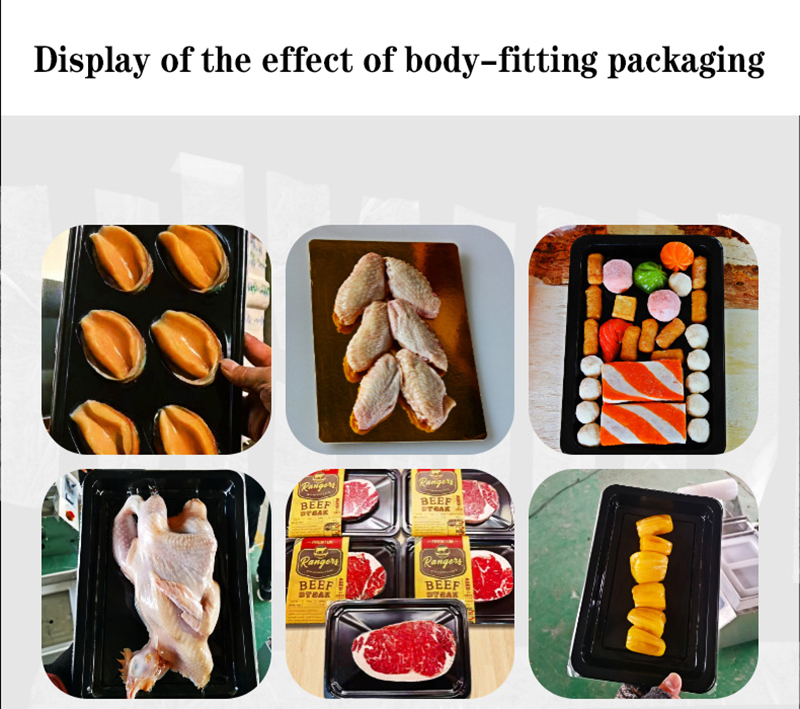

Advantages of using a body-fitting packaging machine

| 1.Flexible installation and high efficiency | A. Bundle the product between the adhesive film and the bottom plate (cardboard or bubble cloth), no matter the shape, size, single or collective combination, the product can be sealed one-time packaging molding, no mold, convenient, fast, efficient, practical.

B. Effectively improve the product appearance and sense of value: the transparent film conforms to the shape of the product and is fixed on the cardboard, which has a strong three-dimensional sense and is convenient for inspection, resolution and touch. Cardboard can be beautifully printed to promote products, which will greatly improve the sense of value and grade of products. |

| 2.Best product protection | A. The product is completely fixed on the bottom plate to be shockproof, friction-proof and shatterproof more effectively, and the product will not be damaged due to handling and transportation, especially suitable for fragile or special-shaped products.

B. Vacuum seal: moisture-proof, anti-oxidation, dustproof, anti-loose parts, can effectively protect the quality of products, prolong the life of products. |

| 3.Low packaging cost | A. Compared with blister packaging without mould production, greatly improve packaging efficiency and reduce packaging cost. B. Save storage and transportation costs: Compared with traditional blister cover, poly dragon and other shock-proof packaging, this packaging can save packaging volume and reduce storage and transportation costs. |

| 4.Strengthen the market competitive advantage | This packaging method has been widely used in the international market and greatly improves the competitiveness of the products in the market. |

Commercial Skin Vacuum Packaging Cold Meat Food Vacuum Packaging Machine

.jpeg)

Main advantages of vacuum packing machine:

1, flexible packaging: no matter the shape, size, single packaging, or collective packaging, vacuum fitting packaging can be a one-time thermoforming sealing packaging, convenient and flexible.

2, high packaging efficiency: vacuum fitting packaging without additional mold, products can be packed at any time, no need to wait for mold.

3, improve the product appearance sense of value and grade: transparent vacuum fitting packaging film complies with the product shape and is fixed on the cardboard, the visual display effect is good, easy to view, distinguish and touch. With fine printed board, can greatly enhance the sense of value and grade of products.

4, the product protection effect is good: the product is completely fixed on the bottom plate, can effectively shock-proof, friction-proof, shatter-proof, in fragile or special-shaped product protection effect is especially prominent.

5, vacuum sealing protection quality: vacuum fitting packaging moisture-proof, anti-oxidation, dustproof, side three, can effectively protect the quality of products, prolong the life of products.

6. Low packaging cost: compared with blister packaging without mould making, vacuum fitting packaging greatly improves packaging efficiency and reduces packaging cost.Save storage and transportation costs: Compared with traditional blixon cover, poly Dragon and other shock-proof packaging, the fitting packaging can save packaging volume and reduce storage and transportation costs.