750 vacuum skin packaging machine mold food grade silicone plate aluminum alloy plate material

.jpeg)

| Name | Data Parameter |

| Name | Vacuum fitting packaging machine |

| Equipment dimensions | 950*950*1170mm |

| Total power | 10.7KW /h |

| Actual working size of studio | 310*390*55mm |

| Machine material | Aluminum alloy, 304 stainless steel |

| Film width | 760mm |

| Power supply voltage | 380V |

| Vacuum time | 8-30 S(adjustable) |

The principle of body fitting packaging is: the composite film with low viscosity is adopted, the material is placed on the tray or film of the lower template, and the heat generated by the heating plate is sent to the vacuum room through the exhaust outlet under the vacuum state, and the low-viscosity composite film is instantly heated to the whole body, and the composite is combined together to achieve the effect of vacuum packaging.

This kind of packaging is to heat the film after softening and then shrink the packaging, so there is no packaging with sharp corners, hard thorns when the phenomenon of the film punctured. The packing has no breakage rate.

There are two modes of this kind of packaging: supporting box (this kind of packaging, can increase the attractive appearance, three-dimensional feeling is particularly strong), can also be used in two film packaging.

.jpeg)

Main advantages of vacuum packing machine:

Advantages of vacuum fitting packaging:

Excellent vacuum and fit tight protection (longer shelf life);

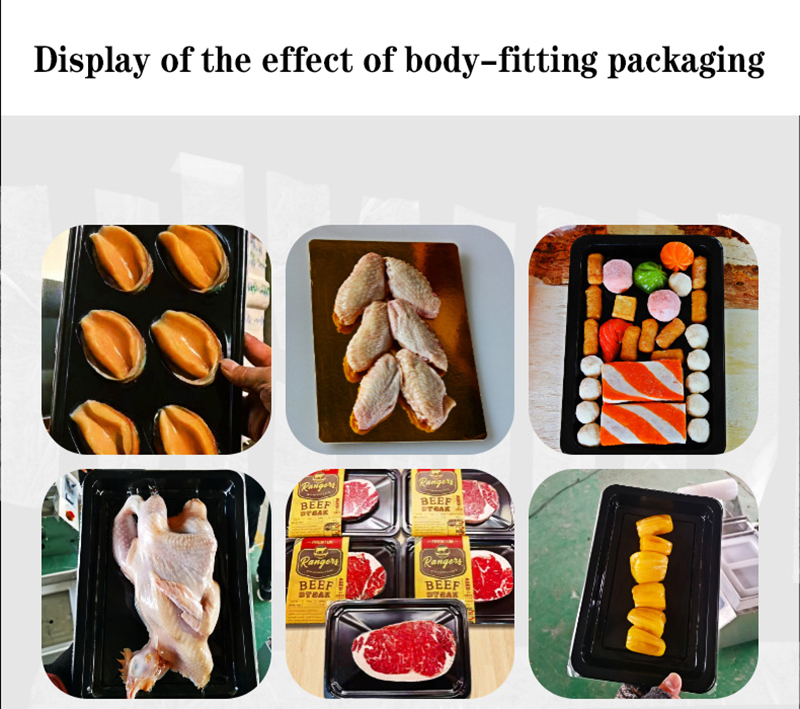

Better packaging display effect (eye-catching);

Can be used to package soft contents;

Prevent frozen spot on fresh meat and seafood products;

No vacuum tunneling and liquid accumulation;

Flexible packaging and high efficiency: the product is bunched between the adhesive film and the bottom plate (cardboard or bubble cloth), no matter the shape, size, single or collective combination, the product can be sealed one-time packaging molding, no mold, convenient, fast, efficient, practical.

Effectively improve the product appearance and sense of value: the transparent film conforms to the shape of the product and is fixed on the cardboard, which has a strong three-dimensional sense and is easy to view, distinguish and touch. Cardboard can be beautifully printed to promote products, which will greatly improve the sense of value and grade of products.

| 1. Product Protection: | Aluminum alloy heating plate teflon anti-stick coating, the upper vacuum chamber is MADE of SUS304 stainless steel,the lower vacuum chamber is made of cast aluminum alloy. |

| 2. Vacuum seal: | Vacuum pressure gauge, xinjie PLC touch screen control, set with start emergency stop button. |

| 3. Automatic film cutter: | Automatic film cutter with protective cover can cut film flat, fast and ensure safety, manual film cutting is no longer used. |

| 4. Optimize the vacuum pipeline: | Optimize the gas path to save the area, equipped with cast aluminum + stainless steel pipeline. |

750 vacuum skin packaging machine mold food grade silicone plate aluminum alloy plate material

Vacuum fitting packaging is a novel commodity packaging technology, favored in the food packaging industry, vacuum fitting packaging is mainly composed of substrate tray and plastic cover film.

The process of body-fitting packaging is as follows: the covered product is placed in the tray, so that the special body-fitting plastic cover film of the covering product is close to the surface of the product under the action of heating and vacuum, and sealed with the substrate tray.

Vacuum fitting packaging is convenient, economical and efficient for products of different sizes and shapes by special transparent fitting film.

Advantages of using a body-fitting packaging machine

750 vacuum skin packaging machine mold food grade silicone plate aluminum alloy plate material

Adopt low viscosity composite film, put the material on the supporting box or film of the lower template, and send the heat generated by the heating plate to the vacuum room through the exhaust outlet under the vacuum state, to heat the whole body of low viscosity composite film instantly, and combine together to achieve the effect of vacuum packaging. This kind of packaging is to heat the film after softening and then shrink the packaging, so there is no packaging with sharp corners, hard thorns when the phenomenon of the film punctured. The packing has no breakage rate. There are two modes of this kind of packaging: supporting box type, paper board type (this kind of packaging, can increase the attractive appearance, three-dimensional feeling is particularly strong), also can use two film packaging.

.jpeg)

.jpeg)

.jpeg)